CV

Here's what I've done so far

Education

M.S.E. in Biomedical Engineering: Imaging and Instrumentation - Johns Hopkins University

2019 - 2020

Relevant coursework: Robot Devices, Kinematics, Design, and Control; Haptic Design; Mechatronics; Biomedical Instrumentation; Surgery for Engineers

I was very fortunate to participate in a 3+1 program where I was able to take graduate level courses and complete my masters instead of graduating early.

B.S. in Biomedical Engineering - Johns Hopkins University

2016 - 2020

Relevant coursework: Control Systems; Robot Sensors/Actuators; Circuits; Build an Imager; Biomedical Data Science; Rehabilitation Engineering

Activities: Treasurer-Theta Tau Professional Engineering Fraternity, Hopkins Emergency Response Unit, BME Design Teams

Experience

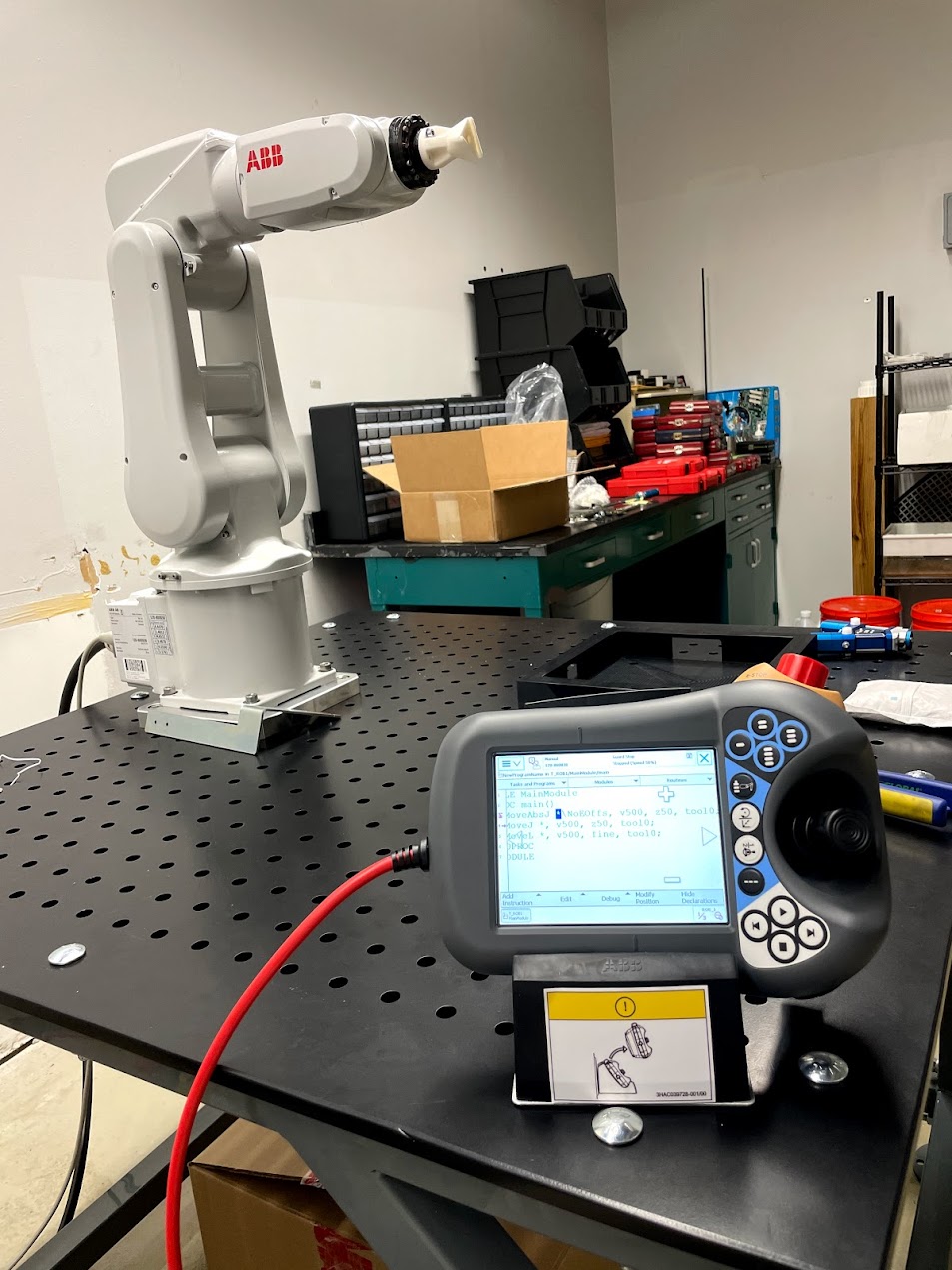

Mechatronics Engineer - Laza Medical

Oct 2024 - Present | Campbell, CA

I've been working on the mechatronic design of a robotic platform that can control an ultrasound probe used in heart procedures

Robotics Engineer - Cellular Vehicles

Oct 2023 - Oct 2024 | Palo Alto, CA

Systems Integration Engineer - Johnson and Johnson

Mar 2022 - May 2023 | Santa Clara, CA

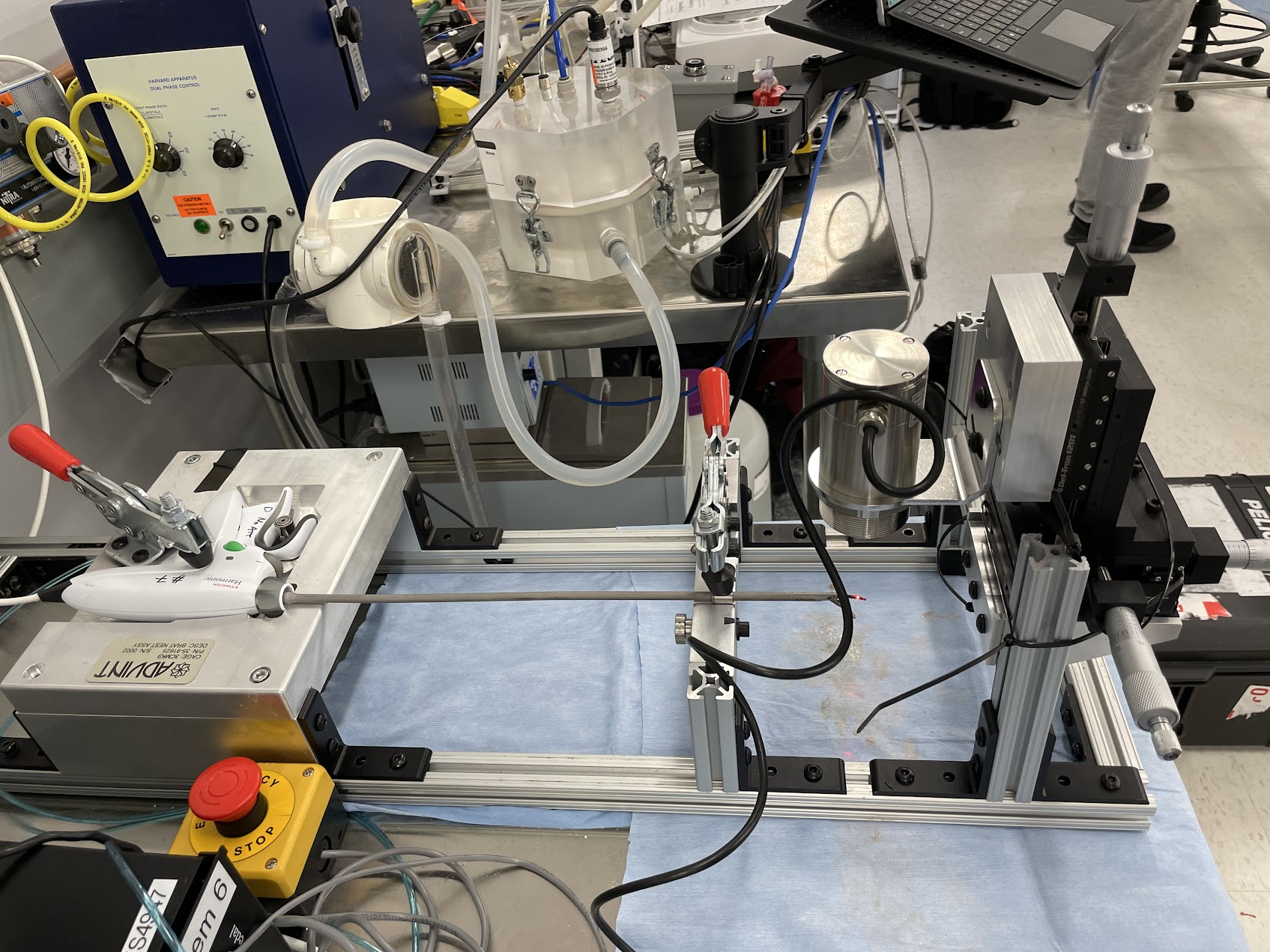

R&D Mechatronics Engineer - Army Research Laboratory

Sep 2020 - Mar 2022 | Aberdeen Proving Ground, MD

Graduate Student Researcher - Terradynamics, Laboratory for Computational Sensing and Robotics

May 2019 - Sep 2020 | Baltimore, MD

Emergency Medical Technician - Johns Hopkins Emergency Response Organization

Nov 2017 - Dec 2019 | Baltimore, MD

Design Studio Teaching Assistant - Johns Hopkins Department of Biomedical Engineering

Sep 2018 - May 2019 | Baltimore, MD

I took a part time job as a teaching assistant for the BME Design Lab, a sort of maker space for BME students to work on any project they wanted. We had everything a maker could need: a basic machine shop, 3D printers, soldering stations and electrical test tools, sewing machines and everything in between. I worked on teaching students how to use the different tools and machines and would help upkeep the machines as well.

Co-Founder, Engineering Lead - Osteocast

Mar 2017 - May 2019 | Baltimore, MD

Algorithms Engineering Intern - Universidad Carlos III de Madrid

May 2017 - Aug 2017 | Madrid, Spain

I did a summer internship with the Biomedical Imaging and Instrumentation Group at the Universidad Carlos III de Madrid as a part of a research abroad program. My work was in developing an image processing algorithm in MATLAB that would improve the CT scans of animals by about 46%. This was done by removing the frames where the animal was breathing from the overall volume of images because they would end up blurring those areas.

Skills

Software

- Python

- C/C++

- MATLAB

- Git, Linux

- Java

Robotics

- Robot Arms, Robot Kinematics

- Control Systems

- Haptics

- Teleoperation

- Simulation

Mechatronics

- PCB & Circuit Design (Fusion 360, KiCAD)

- Hardware Design

- Microcontrollers/Raspberry Pi

- Sensors/Actuators

- Oscilloscopes

- EtherCAT, SPI, I2C

General

- CAD (SolidWorks, Onshape)

- 3D Printing

- Rapid Prototyping

- Machining

- Laser Cutter, Water Cutter

- Systems Integration

- GD&T

Patents

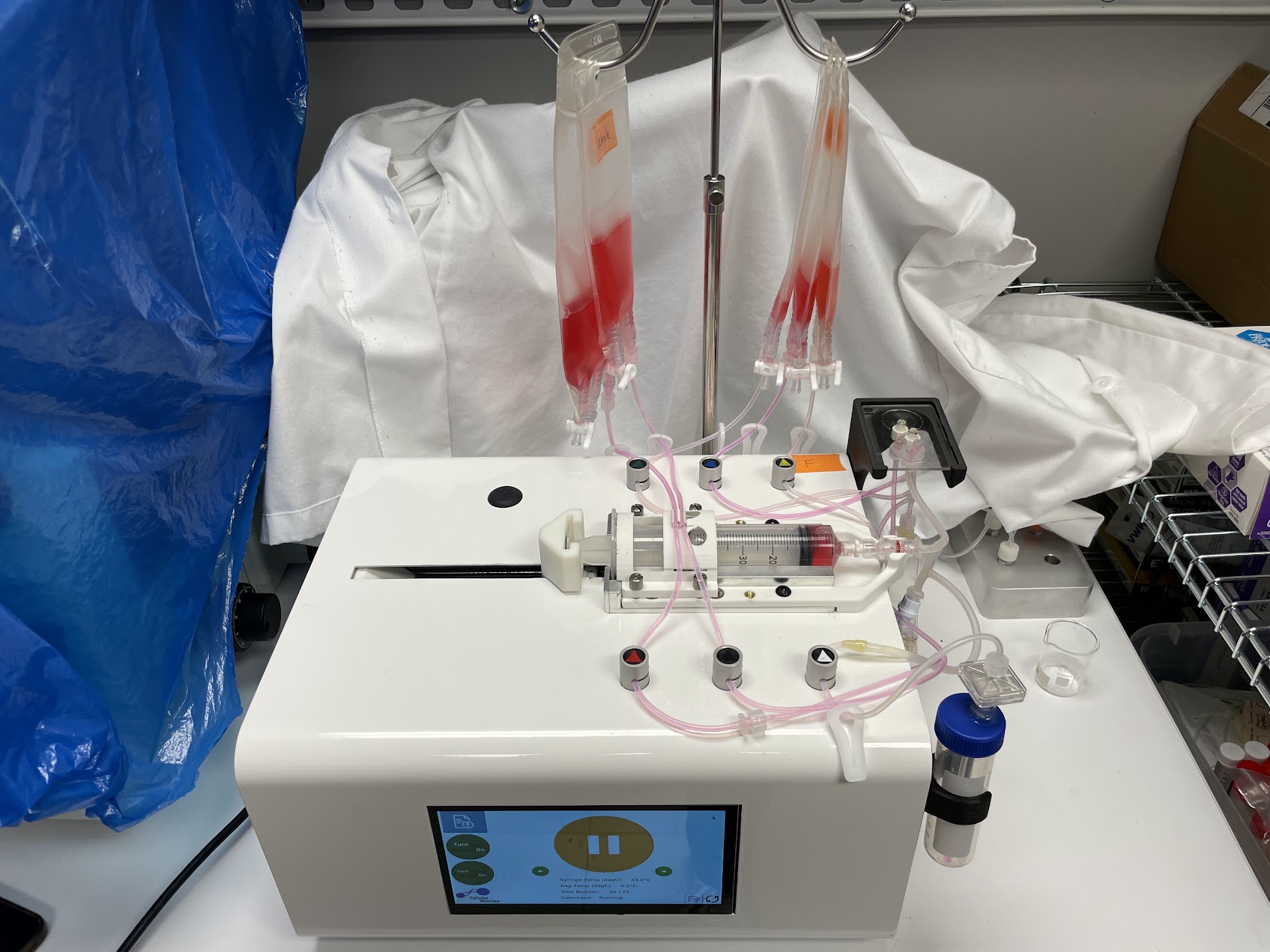

Microfluidic systems, devices, and kits for suspension therapy preparation and/or infusion and methods for use

Patent No. WO2025213101A1 | 2025 (Pending)

A microfluidic device for processing therapeutic suspensions (such as CAR T-cell therapies) using microfluidic inertial focusing to separate, wash, and concentrate therapeutic agents from waste media prior to patient infusion.

Method and system for estimating temperature of an end effector of an ultrasonic instrument

Patent No. XXXXXXX | 2024 (Pending)

A surgical system that estimates the temperature of an ultrasonic surgical blade in real-time using resonance frequency measurements and temperature models during both heating and cooling cycles.